We hear plenty of talk about energy monitoring in manufacturing, but there are many inaccurate myths floating around too! So it’s time to look at what’s real and what’s not. Are you ready to challenge your assumptions? We think you might be surprised.

Separating the myths from the facts can open up ways to improve how your manufacturing facility runs. It can also lead to some serious cost savings. Let us show you how…

Myth 1: Energy monitoring is too expensive and the ROI is unclear for our site

We get it. Budgets are tight, and long-term payouts can be hard to justify. You’re always watching the budget, and the idea of spending a lot on a new energy monitoring system can seem daunting. Many people believe the upfront cost is just too high for their facility, and this is a common concern we come across. But businesses could collectively be wasting more than $30 billion of energy per year!

This worry about cost often comes from how things used to be. Older systems could be expensive and complicated. So, it’s understandable why you might think the return on investment isn’t clear enough, and you might feel it would take too long to see any real financial benefits.

We’ve seen how easy it is to overlook potential efficiencies if the initial outlay seems too much of a hurdle. However, by hesitating because of these cost concerns, you might be missing out. Holding back means you could be passively accepting high energy bills, and these old ideas about costly technology can stop you from finding some big, quick savings.

Fact 1: Modern energy monitoring systems offer clear affordability and rapid ROI

Let’s clear up that cost myth straight away. Modern energy monitoring systems are a whole different ball game. The latest innovative technology is designed to be much more affordable and cost-effective for businesses like yours.

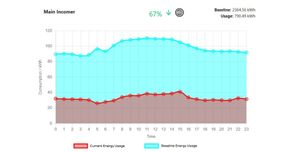

In fact, many sites see a return on their investment within months, not years. How? These systems immediately pinpoint where energy is being wasted. You get clear, real-time data that shows you exactly what’s going on. There’s no guesswork involved, which makes a big difference to your bottom line quickly. And the savings opportunities are substantial. Businesses in the manufacturing sector have the potential to reduce energy consumption by 25%, cutting emissions, improving sustainability, and reducing running costs.

Imagine seeing precisely which machines are using too much energy. Or finding out when equipment is left running unnecessarily. The detailed information from an energy monitoring system translates directly into practical steps you can take. You can then make informed decisions which will help to reduce consumption, make better use of your equipment, and really cut down your operational costs. The financial sense of intelligent energy monitoring systems becomes very clear, very fast.

Myth 2: Manual readings are sufficient and tell us everything we need to know

Another common idea we hear is that taking manual meter readings now and then is good enough. Perhaps your team already does this. You might think these occasional checks give you all the energy data your manufacturing plant needs, and it’s a routine that many facilities have relied on for years.

However, relying only on manual data means inefficiencies can stay hidden, and you might be missing critical information that could save you money.

Fact 2: Advanced energy monitoring provides powerful data and energy management

Now, let’s tackle that idea about manual readings being good enough. Modern energy monitoring solutions offer something far better. They give you incredibly detailed, real-time data, and this information is much more powerful than any manual check could ever be. It can also reduce a lot of the stress that comes with managing energy costs without full visibility.

Energy monitoring systems pinpoint specific areas for improvement with amazing accuracy. They highlight patterns in energy usage and identify areas of energy waste that can be targeted to save both energy and money. These insights often lead to major efficiency gains that were previously invisible. You can see patterns and problems you’d never spot with just occasional readings. Understanding exactly where energy is going, minute-by-minute, is a huge step up. Continuous energy monitoring can lead to a 10-20% reduction in energy consumption when combined with active control and operational improvements.

Myth 3: Implementation of a full energy management system is too disruptive

There’s often a fear about the disruption involved in installing a full-blown energy monitoring system. Production managers worry it will cause major downtime, and nobody wants to halt production and ultimately impact on their bottom line.

The thought of complex integration challenges with existing machinery can also be a real concern. So, it’s easy to stick with what you know, even if it’s not perfect. However, the fear of disruption can actually stop you from getting the tools that will make operations smoother and more efficient.

Fact 3: Modern energy management solutions can be implemented with surprisingly minimal disruption

Let’s talk about the installation process. Modern energy management systems are designed for ease of use. The installation process is surprisingly non-disruptive - it can even be as easy as plug-and-play! The technology can typically be safely installed on a live system and is usually installed at the distribution board level. This means no disruption on the shop floor and no shutdowns affecting your daily operations.

Internet of Things (IoT) technology allows for smooth integration without causing big interruptions to your work. You then get intuitive dashboards that make powerful data easy to understand, without the need for extensive training. Your team can access and use the information without major operational hold-ups, and it’s all far simpler than you might think.

Transform your energy management with Eniscope

We’ve looked at some common myths about energy monitoring, and we’ve also exposed the profitable facts. Old ideas about high costs and tricky setups just don’t apply to today’s systems. In fact, modern solutions like Eniscope offer clear financial benefits and are much easier to get up and running.

So, it’s time to use these facts to your advantage. You can transform your manufacturing facility’s energy efficiency and make your operations far more cost-effective with our award-winning solution. We believe our Eniscope energy management system can make these profitable facts a reality for you.

Are you ready to dive in deeper? Partner with Best.Energy to begin your energy monitoring journey and experience the power of Eniscope in manufacturing.